What Makes Industrial Acoustic Panels Stand Out In the Workplace?

In the bustling world of industry, where the hum of machinery and the clang of equipment often reign, the subtleties of acoustics play a pivotal role that's more significant than meets the ear.

Acoustic considerations extend far beyond concert halls and recording studios; they deeply influence the productivity, safety, and ambiance of industrial settings. One essential tool in mastering the symphony of sounds within these spaces is the industrial acoustic panel.

Functionality of Industrial Acoustic Panels

Sound Absorption vs. Sound Insulation

At first glance, the terms "sound absorption" and "sound insulation" might appear interchangeable, but they represent distinct mechanisms with varying goals.

Sound absorption primarily deals with reducing the intensity of sound reflections within a space, thus decreasing echoes and minimizing overall noise levels. This is where industrial acoustic panels excel, as they're designed to absorb sound energy through specialized materials and configurations. In contrast, sound insulation focuses on blocking the transmission of sound from one space to another, creating a soundproof barrier.

Mechanisms of Sound Absorption in Acoustic Panels

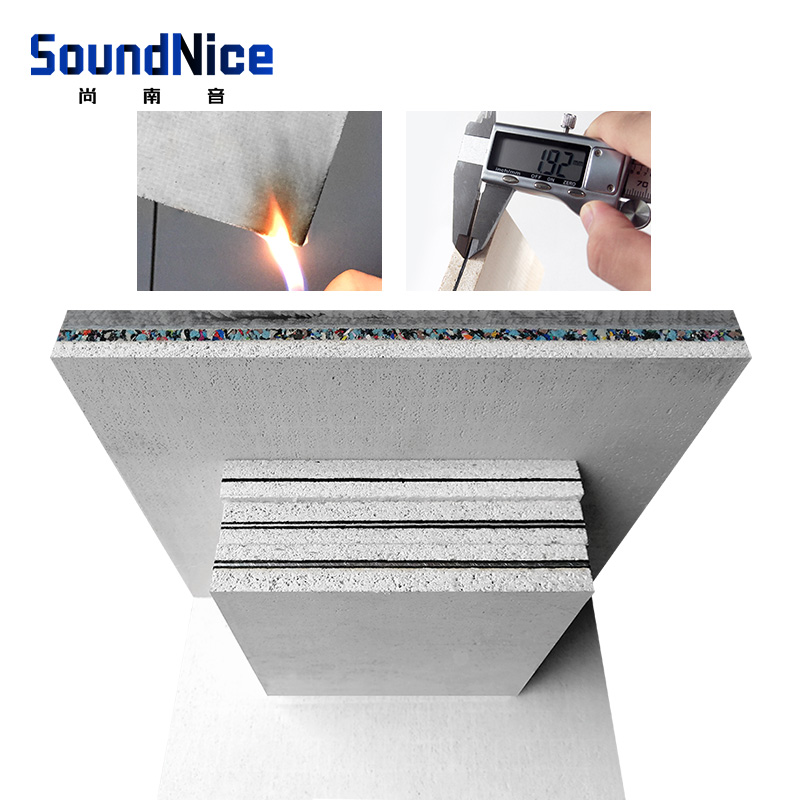

The magic of industrial acoustic panels lies in their ability to transform sound energy into heat, mitigating its reflection back into the environment. This absorption is achieved through the utilization of porous materials, such as mineral wool or foam, which trap sound waves and convert their kinetic energy into small amounts of heat. Additionally, these panels employ strategies like diffusion and transmission to disperse sound waves, preventing the formation of standing waves that can lead to unwanted resonances.

Applications of Industrial Acoustic Panels

Manufacturing and Production Facilities

In the heart of production plants, the machinery's rhythmic cadence is often accompanied by a cacophony of noise. This auditory backdrop not only affects workers' concentration but can also pose long-term health risks. Industrial acoustic panels come to the rescue by absorbing excess noise, creating a more serene work environment that promotes focus and reduces stress. Moreover, by curbing noise pollution at its source, these panels contribute to enhancing worker safety.

Warehouses and Distribution Centers

The vast, open spaces of warehouses tend to amplify sound, resulting in a soundscape characterized by echoes and reverberations. Installing industrial acoustic panels strategically within these spaces serves multiple purposes. Firstly, they curtail the echoes, fostering better communication among staff members and improving overall audibility. Secondly, these panels help in managing sound reflections, allowing for a more controlled acoustic environment that enhances both employee comfort and productivity.

Power Plants and Energy Generation Facilities

The industrial behemoths that are power plants churn out a symphony of mechanical and electrical sounds, often at deafening volumes. Given the high-intensity nature of these environments, traditional construction materials fall short of curbing the noise. Industrial acoustic panels step in as the perfect remedy, absorbing and mitigating sound waves generated by turbines, compressors, and generators. By doing so, they not only protect workers' hearing but also minimize the potential impact of noise pollution on surrounding communities.

Considerations for Selecting and Installing Industrial Acoustic Panels

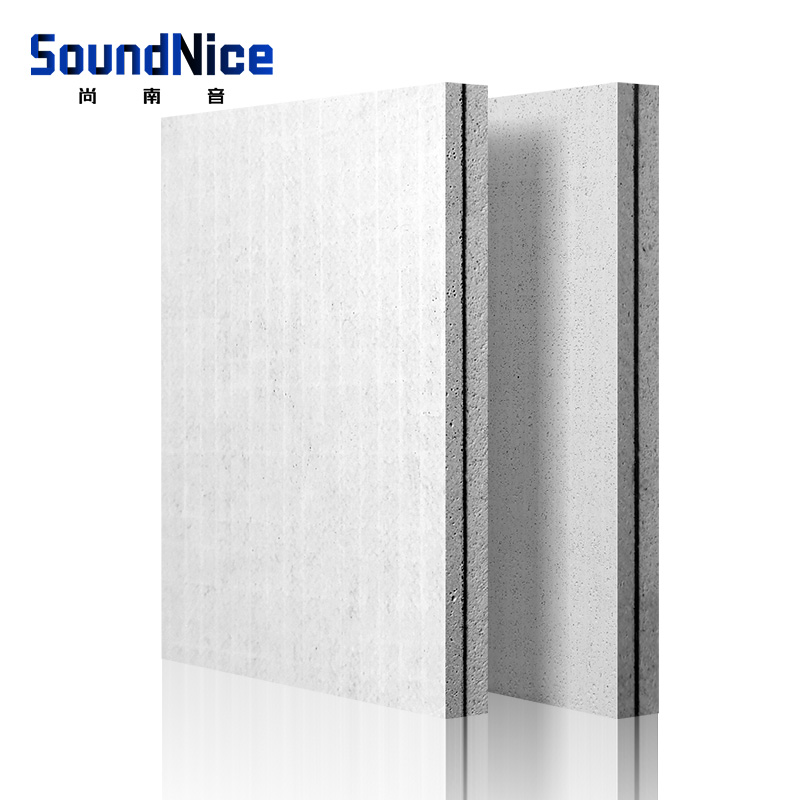

Acoustic Panel Materials and Design

When venturing into the realm of industrial acoustic panels, it's essential to be acquainted with the metrics that gauge their performance. The Noise Reduction Coefficient (NRC) measures a panel's ability to absorb sound across different frequencies, while the Sound Transmission Class (STC) evaluates its capacity to block sound. Selecting panels with suitable NRC and STC ratings is crucial for achieving the desired level of noise reduction. Moreover, the thickness and density of the panel, along with the specific materials used, impact its overall effectiveness.

Customization and Aesthetics

Functionality need not be devoid of style. Modern industrial acoustic panels offer a range of customization options that seamlessly integrate them into the existing environment. From color palettes that match corporate branding to designs that evoke a sense of cohesion, these panels serve both functional and aesthetic purposes. Whether camouflaging within the surroundings or standing out as artistic elements, industrial acoustic panels can be tailored to suit diverse preferences.

Installation Techniques and Positioning

The effectiveness of industrial acoustic panels hinges not only on their quality but also on their placement. Professional installation ensures that panels are strategically positioned to target areas with the most significant sound energy. While DIY approaches are possible, the expertise of professionals ensures optimal results. Furthermore, correct installation prevents issues like gaps or misalignment, which can compromise the panels' performance.

Conclusion

Industrial acoustic panels perform well in noise control, revolutionizing industrial spaces by curbing noise pollution, enhancing productivity, and promoting a safer environment.

With careful selection, customization, and expert installation, Tianjie industrial acoustic panels stand as a testament to the marriage of engineering and aesthetics in the pursuit of acoustic excellence. Please feel free to contact us at [email protected] for more details!

Leave a comment