-

Whatsapp

+86 13336466016 -

Call Us On

+86 13336466016 -

Mail Us

[email protected]

- Home

- Acoustic Products

- Polyester acoustic panel

- 3D PET acoustic panel

- Ceiling polyester acoustic panels

Ceiling polyester acoustic panels

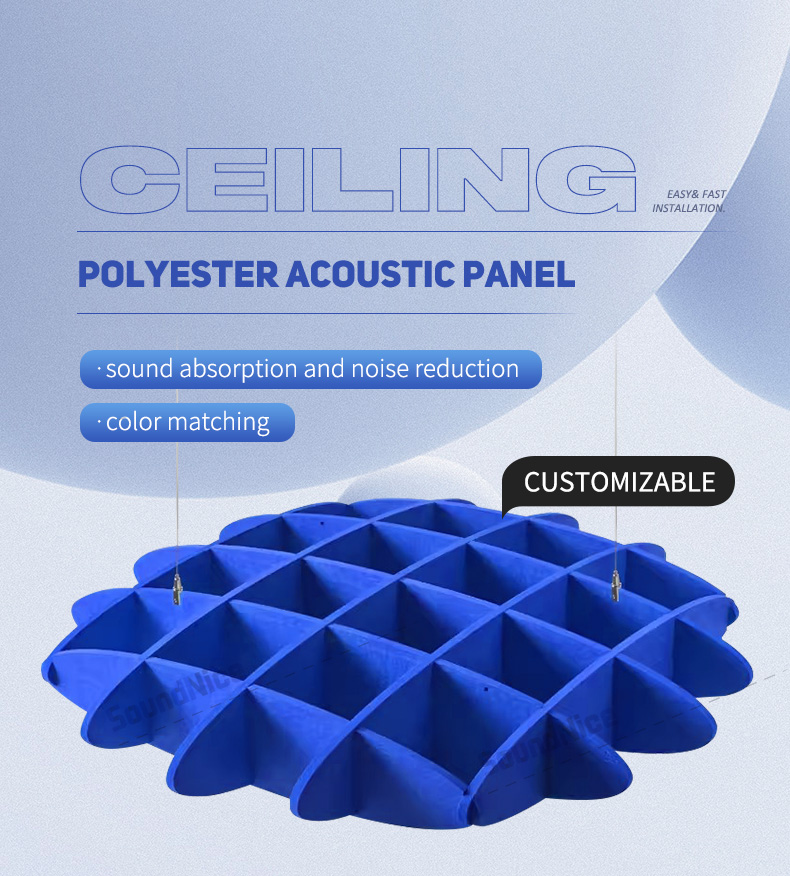

It has the characteristics of high density,non combustion,wide sound-absorbing frequency band,decoration,simple construction,easy cutting and no dust pollution.The performance of thr high-quality version can reach Level B of flame retardant and Leval E of environmental protection.

Hundreds of colors are available.The color is fashionable and gorgerous.You can cut various shapes at will,which can meet the customers' diversified acoustic and decoration neets.

The sound absorption characteristics of Ceiling polyester acoustic panels are similar to those of other porous materials. The sound absorption coefficient increases with the increase of frequency. The high-frequency sound absorption coefficient is very large. The cavity on the back and the spatial sound-absorbing body formed by it can greatly improve the material's performance. Sound absorption performance.

The noise reduction coefficient of Polyester Fiber Acoustic Panel is about 0.8-1.10, which becomes a wide-band high-efficiency sound-absorbing body. At the same time, it has the advantages of non-combustibility, anti-collision, decoration, no dust pollution, and simple construction.

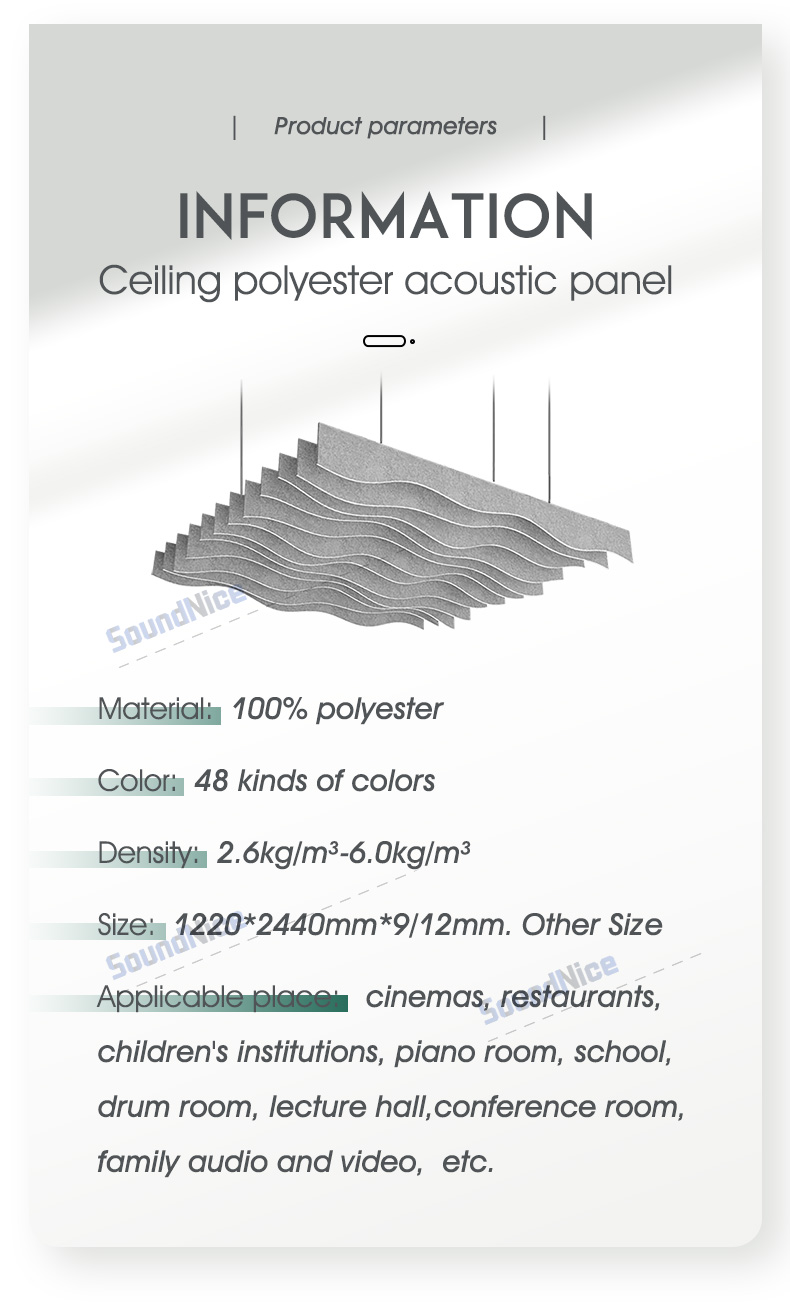

Product parameters

Name:Ceiling polyester acoustic panel

Material: 100% polyester fiber

Density: 160-229kg/㎡

Color: hundreds of colors (please contact customer service)

Environmental protection grade: E1

Details

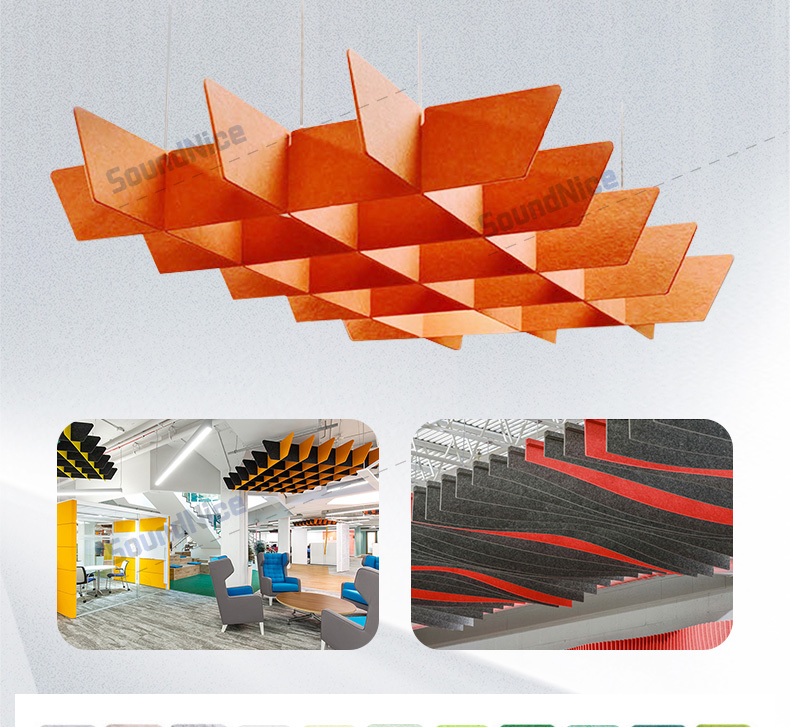

A. decoration:

PET Fiber Acoustic Panels come in dozens of colors and can be assembled into various patterns. The surface shape is flat, square (mosaic Shape), wide strips, thin strips, the plate can be bent into a curved shape. It can make the interior wall design more flexible and changeable and effective. Even geometric perforation and cutting technology can be printed on the PET acoustic panels through the computer.

B. Acoustic function

100% Polyester fiber is hot-pressed with high technology and made in the shape of cocoon cotton to achieve density diversity to ensure ventilation, and become a high-quality product in sound absorption and heat insulation materials. The highest sound absorption coefficient is above 0.9 in the noise range of 125~4000Hz. , The sound absorption coefficient increases with the increase of the frequency. According to different needs, the reverberation time can be shortened to clear the sound impurities, improve the effect of the influence, and improve the clarity of speech. Become a broadband high-efficiency sound-absorbing panel.

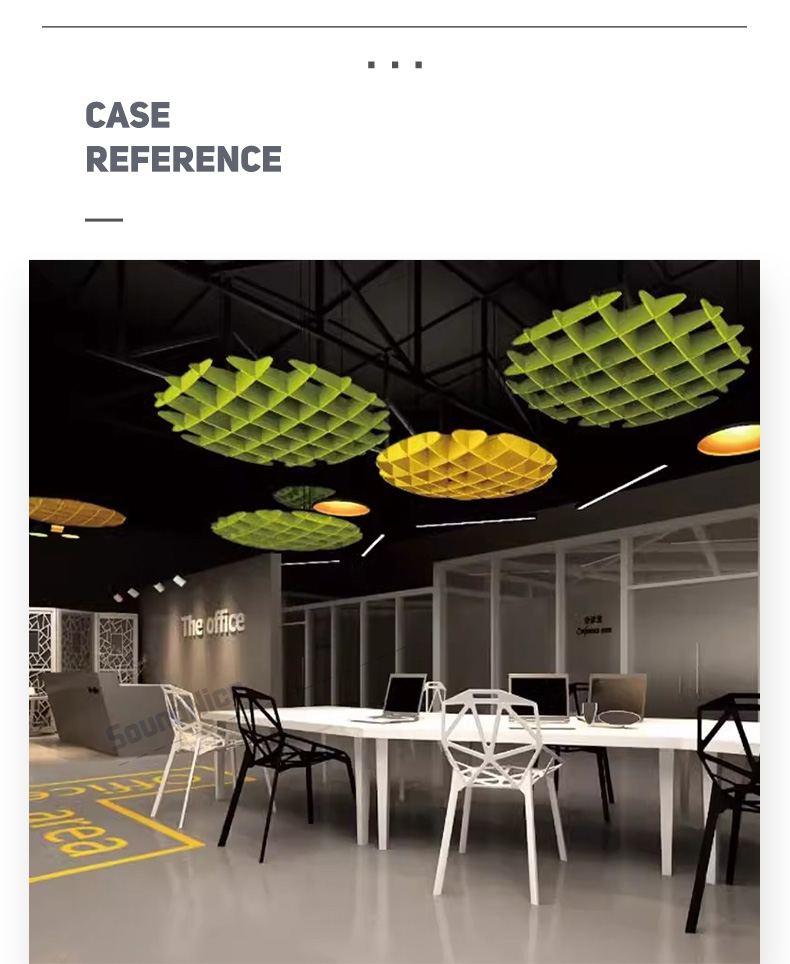

C. Applicable place

Fiber Polyester Acoustic Boards are currently widely used in movie theaters, interrogation rooms, public security bureaus, piano rooms, drum rooms, recording studios, broadcasting rooms, TV stations, business offices, multi-function halls, conference rooms, studios, auditoriums, stadiums, and entertainment Places, KTV boxes and other places with higher acoustic requirements, and at the same time, the current family villas have also begun to be widely used, especially the basement ceiling and indoor walls.

Cinema wall installation Polyester Sound Absorber

Polyester Sound Absorption Panels installed on the wall of the meeting room

Install PET Acoustic Wall Panels on the walls and ceilings of the piano room and drum room

Cinema wall installation PET Acoustic Wall Panels

Installation of anti-collision PET Soundproofing Acoustic Boards on the wall of the Public Security Bureau

Installation of anti-collision PET Fiber Acoustic Panels on the ceiling and wall of the interrogation room

D.installation method

During construction, it is necessary to cut the surface of the PET Wall Acoustic Panels. It is recommended to use a steel ruler or alloy square steel as a ruler when cutting. Do not use wooden strips or soft materials as a ruler to avoid the cutting line from being straight and causing splicing gaps. Too large or distorted. In order to relatively reduce the splicing gap, the blade can be tilted inward by 0.5-1mm during cutting, so that the interface surface forms an inner bevel, which makes it easy for the board to be connected during construction and reduces the gap.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.