-

Whatsapp

+86 13336466016 -

Call Us On

+86 13336466016 -

Mail Us

[email protected]

- Home

- Acoustic Products

- Grooved acoustic panel

- Wooden acoustic panel

- Grooved Acoustic Panel

Grooved Acoustic Panel

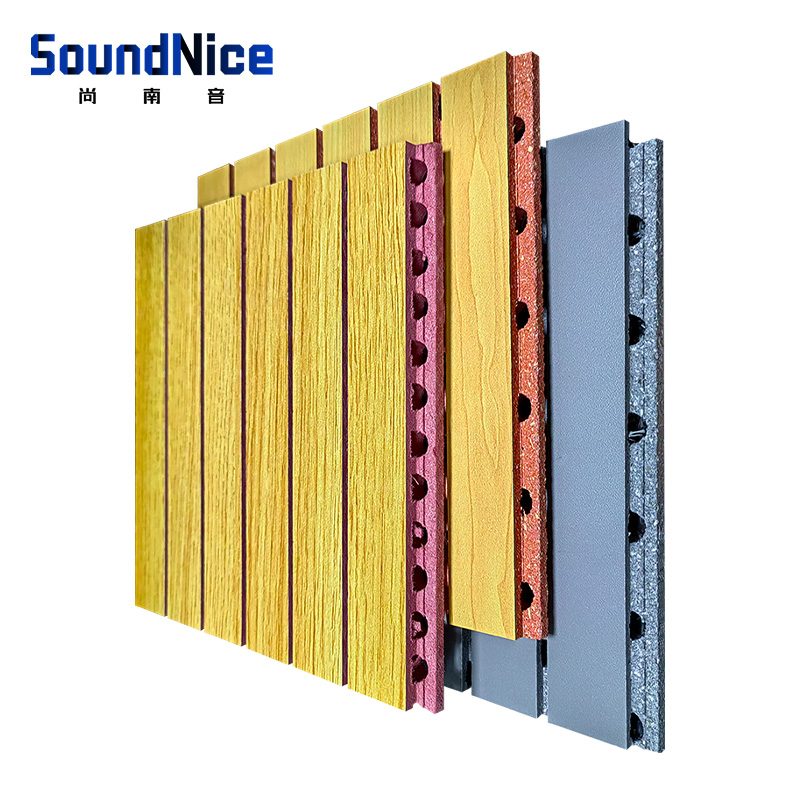

The grooved wood sound-absorbing board uses the structure of slotting on the surface and perforation on the back to change and control the sound emission to achieve a good sound absorption effect. Different textures and colors are available for the finishes, and the high-end appearance can be used for ceiling and wall.

Product parameters

Name: Grooved Acoustic Panel

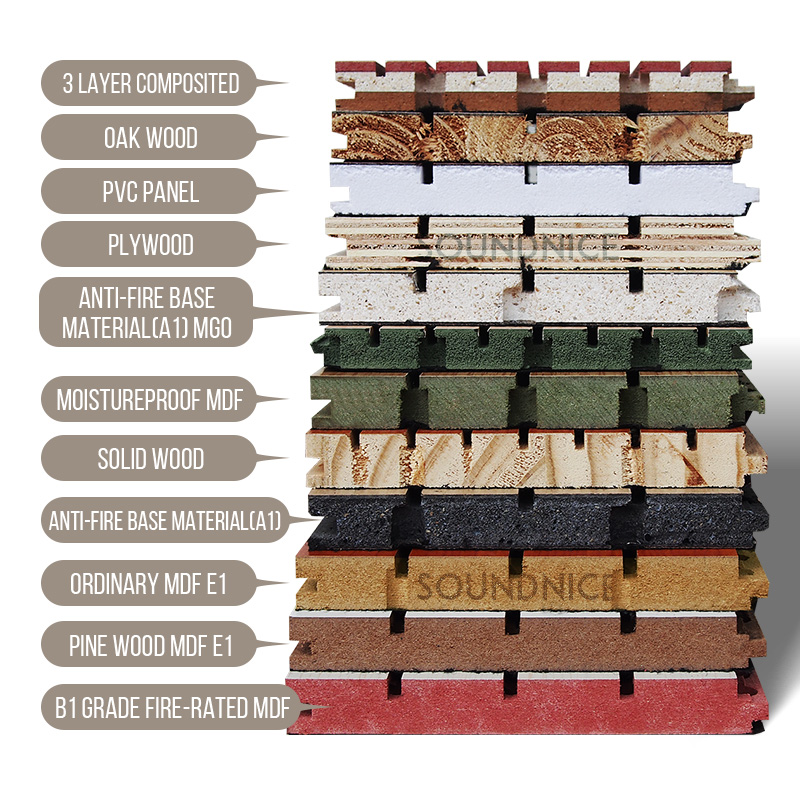

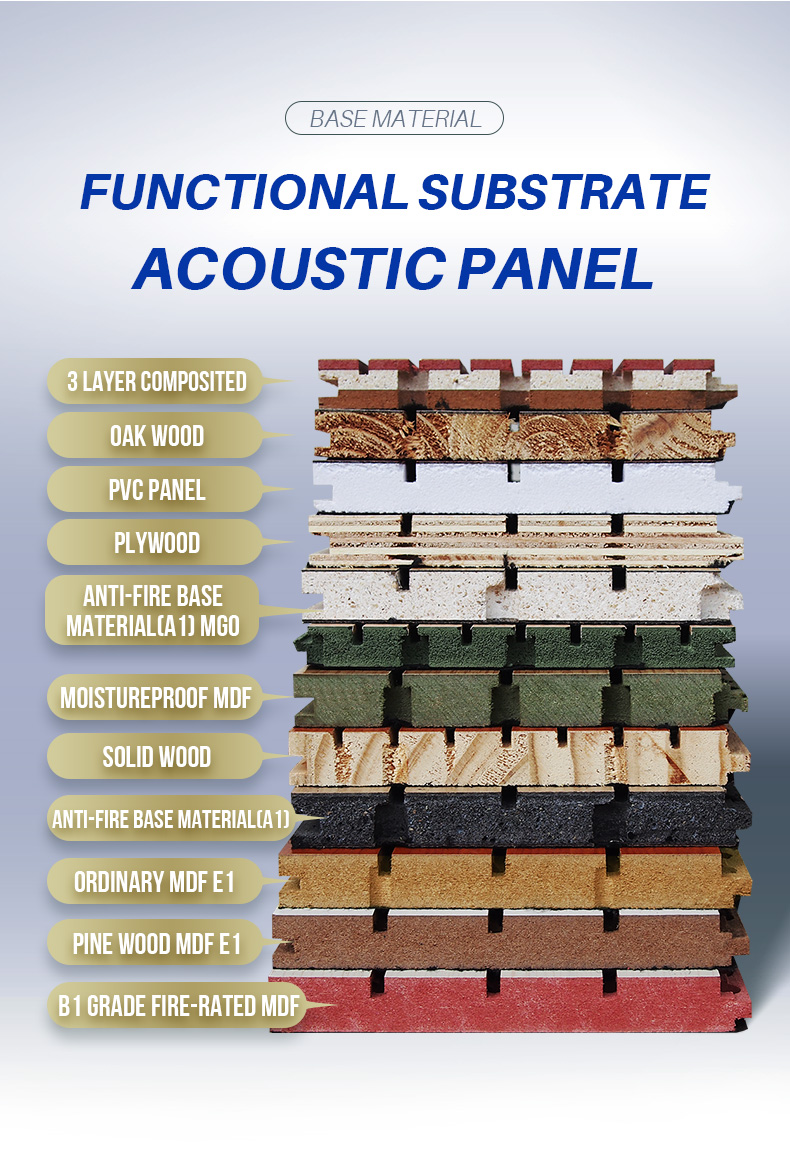

Base material: MDF/HDF/MGO

Size: 2440*132mm,2440*197mm

Thickness: 12,15,18mm

Allowable tolerance: width ±0.1mm length:±2mm

Finishes: melamine, veneer, HPL, pvc(customized finish colour ,and free samples)

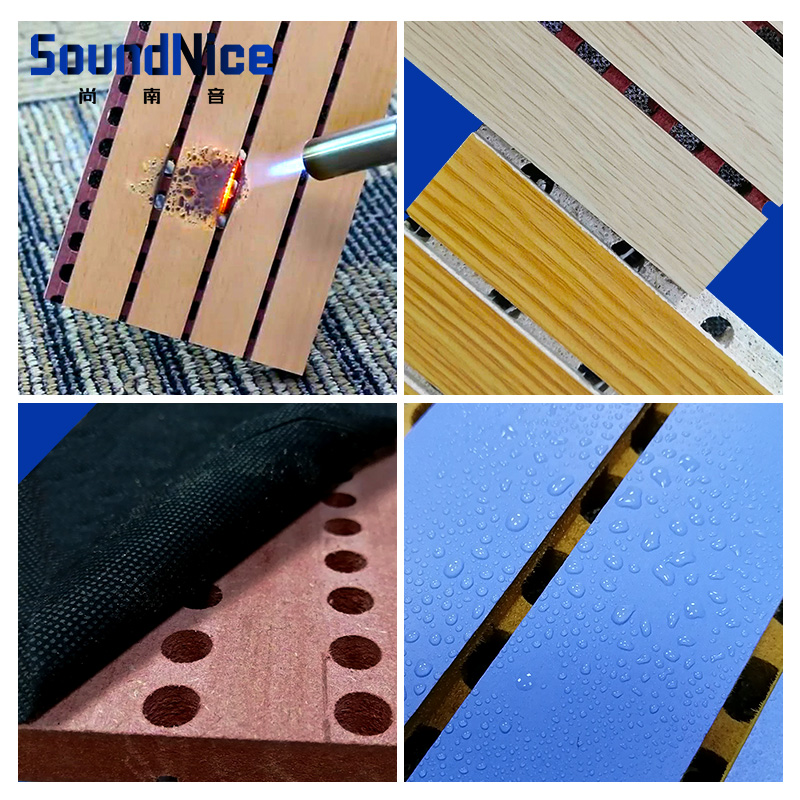

Back acoustic fleece: fireproof A class

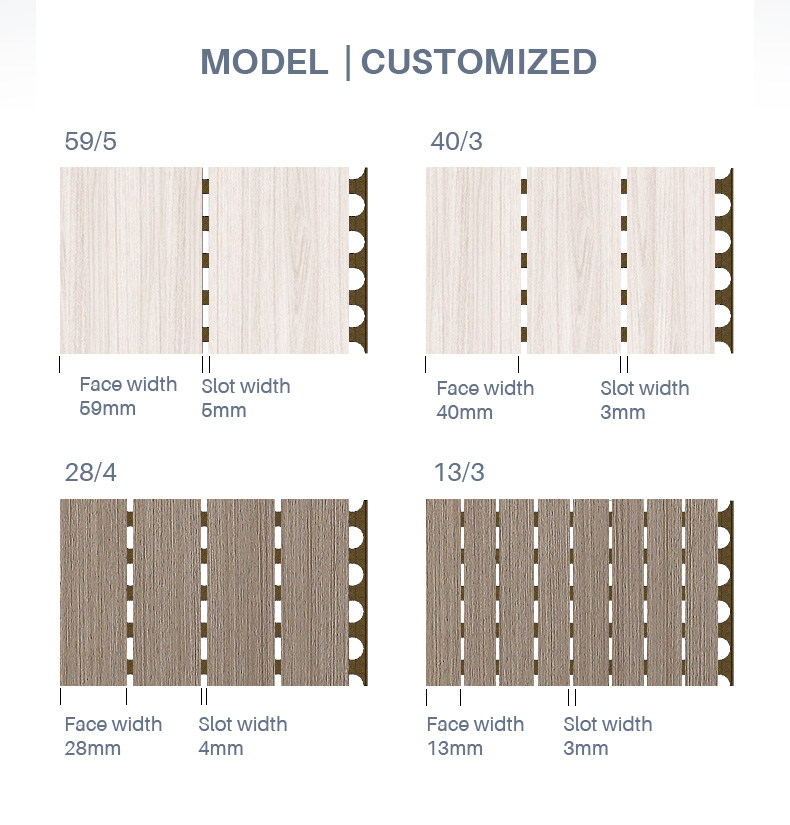

Model: 59/5,40/3,8/3,28/4,18/3,5/3,13/3, customized

Applicable places: meeting rooms, lecture halls, studios, recording studios, bands,

practice rooms, indoor stadiums and other places with high acoustic requirements.

Details

A. Base material characteristics:

1) Science and technology industry-a variety of materials are based on the principle of acoustics, with reasonable coordination, with excellent noise reduction and sound absorption performance, especially for medium and high frequency sound absorption.

2) Art-both natural wood texture, simple and natural; also has a bright and bright style that reflects the modern rhythm, elegant decoration, can be decorated with natural wood grain, patterns and other decorative effects as needed to provide a good vision enjoy.

3)Environmental protection-the solid wood substrate meets the national environmental protection standards, the formaldehyde content is extremely low, and the product also has the fragrance of natural wood. The company can also customize E0-level zero-formaldehyde wooden sound-absorbing panels according to customer needs.

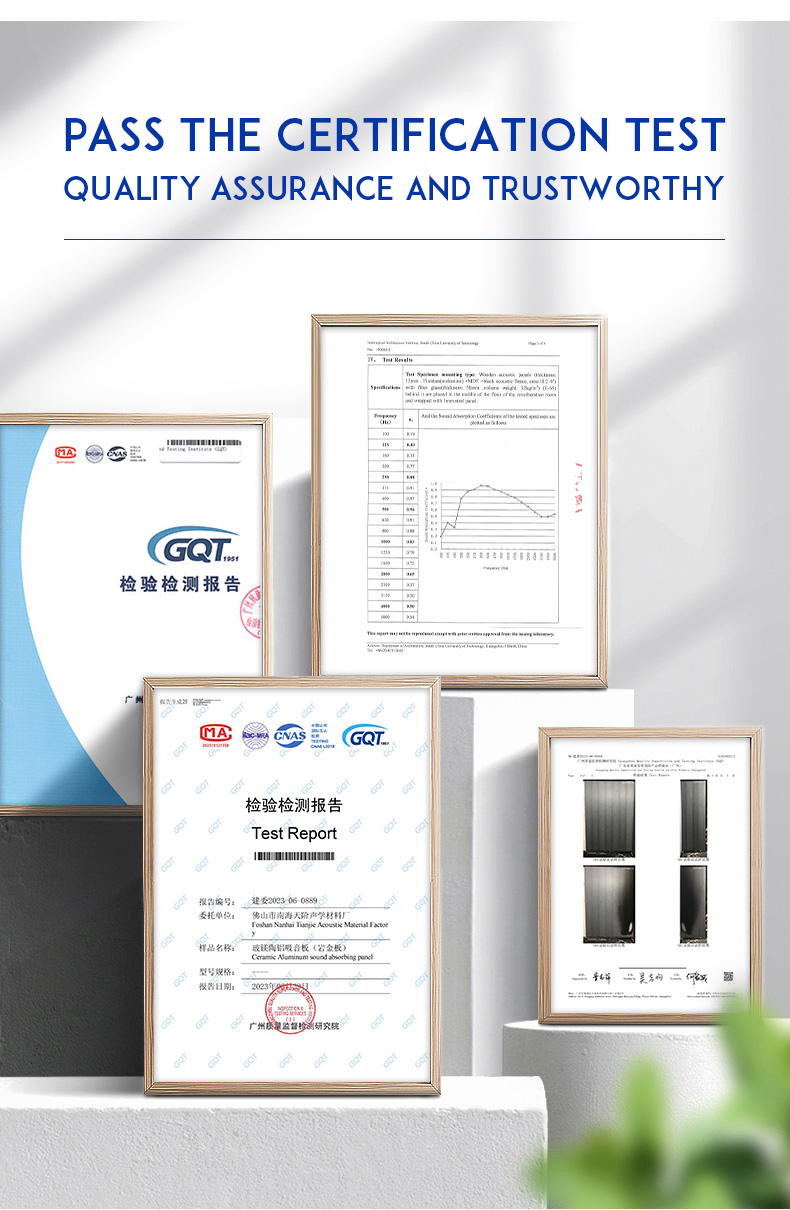

4) Safety and fire protection-the base material has the highest fire protection grade B1 of sound-absorbing board. This point has been tested and passed by the national authority.

5) Industrial production-change the extensive production of traditional building materials, use fully automatic computer control equipment, large-scale standardized production, that is, increase production capacity, but also ensure product quality.

B. Applicable place

High-strength sound-absorbing places: opera houses, theaters, multi-function halls, conference rooms, studios, concert halls, business offices, auditoriums, gymnasiums, schools, hotels.

Entertainment venues: entertainment city, KTV, dance hall, private room.

All in all: it is suitable for places that require both decorative effects and acoustic requirements.

Wooden Grooved Acoustic Panels for wall mounting grooves in meeting rooms

Customized Grooved Acoustic Panels for wall installation grooves in the lecture hall

Grooved Wooden Acoustic Panels for wall mounting grooves in school multifunctional classrooms

Customized Wooden Grooved Acoustic Panels for walls and ceilings in recording studios

Office wall and ceiling Grooved Wood Acoustic Panels

C.installation method

1. Hanging installation method: install the hanging board on the wall, the keel or the object that needs to install the Grooved Wooden Acoustic Panels, and install the hanging board on the Grooved Wooden Acoustic Panels at the same time, and then hang the sound-absorbing board directly.

2. Nail-shooting installation method: Install wooden keel or blockboard on the wall or the object that needs to be installed with the sound-absorbing board of the sky slot, and use the nail to directly nail the sound-absorbing board to the wooden keel or blockboard. It can also be used in conjunction with glue. (This method is suitable for the installation of fabric sound-absorbing panels with back panels or wooden frames).

3. Decorative strip installation method: use decorative strips to fix it on the wall, keel or objects that need to be decorated with sound-absorbing panels. It can also be used with the above methods to make slotted sound-absorbing panels.

D.Packing and transportation

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.