-

Whatsapp

+86 13336466016 -

Call Us On

+86 13336466016 -

Mail Us

[email protected]

- Home

- Acoustic Products

- Wood wool acoustic panel

- Wood wool acoustic panel

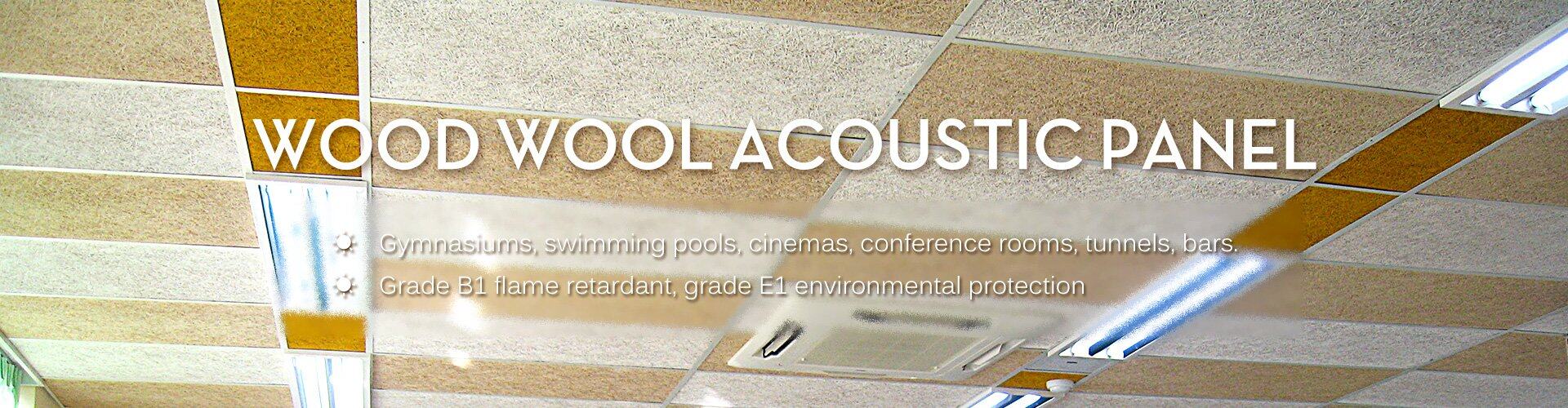

Wood wool acoustic panel

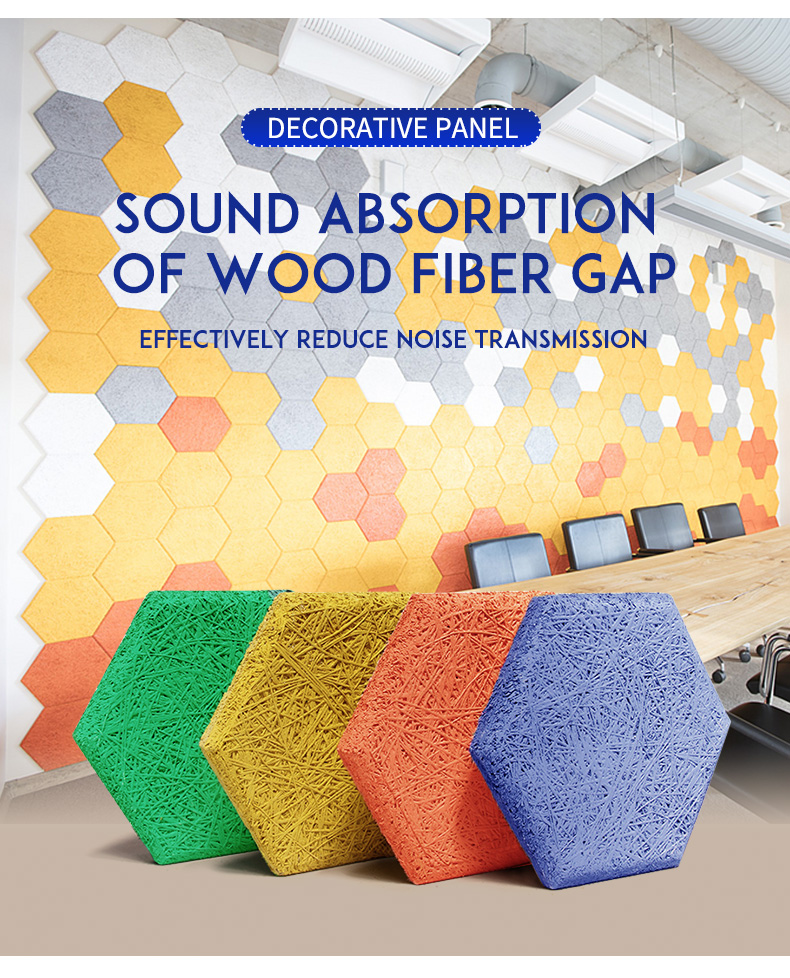

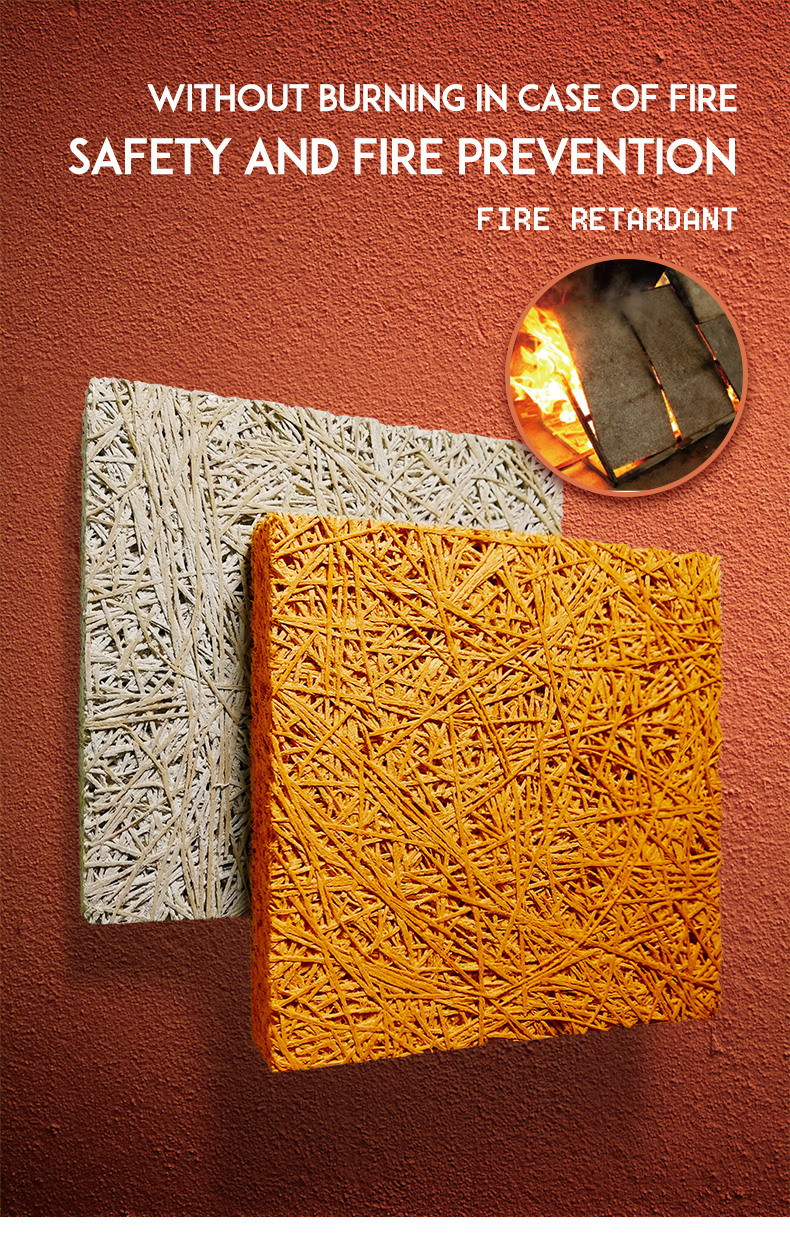

Wood wool acoustic panels, combined with inorganic hard cement binders, are manufactured under the conditions of high temperature and high pressure using a continuous operation process.

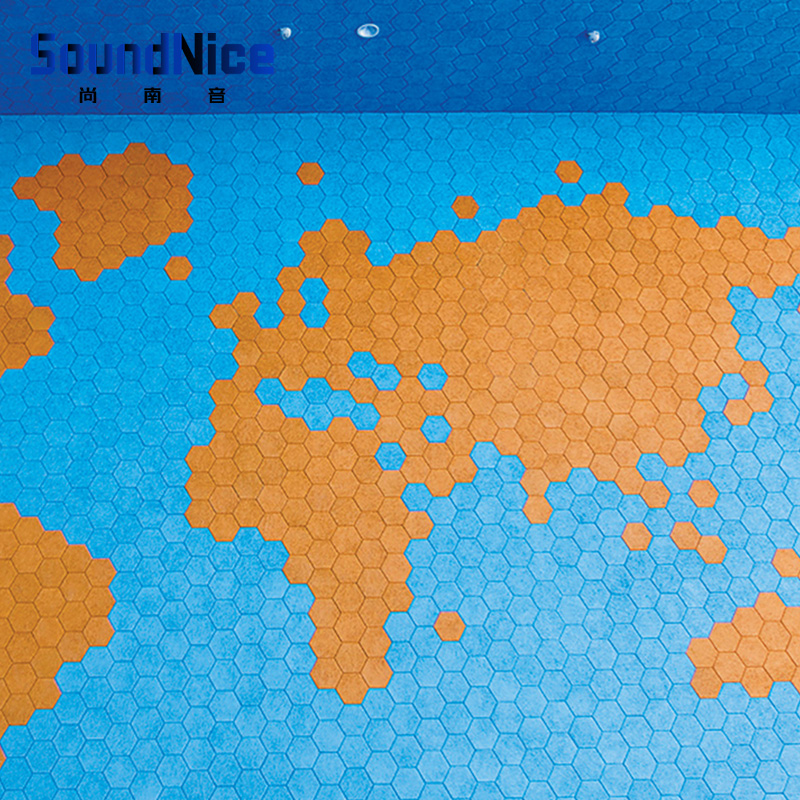

The wood wool acoustic panels has a unique appearance and good sound absorption-the unique surface silky texture gives people a primitive and rough feeling, which satisfies the modern people's idea of returning to nature. The surface can be painted and painted.

Product parameters

Product name: wood wool sound-absorbing board

Substrate: poplar fiber + inorganic cement binder

Color: primary color, spray paint

Density: 580kg/m³

Width: 1220mm

Length: 2440mm

Thickness: 15mm, 20mm, 25mm,35mm

Details

A.Features:

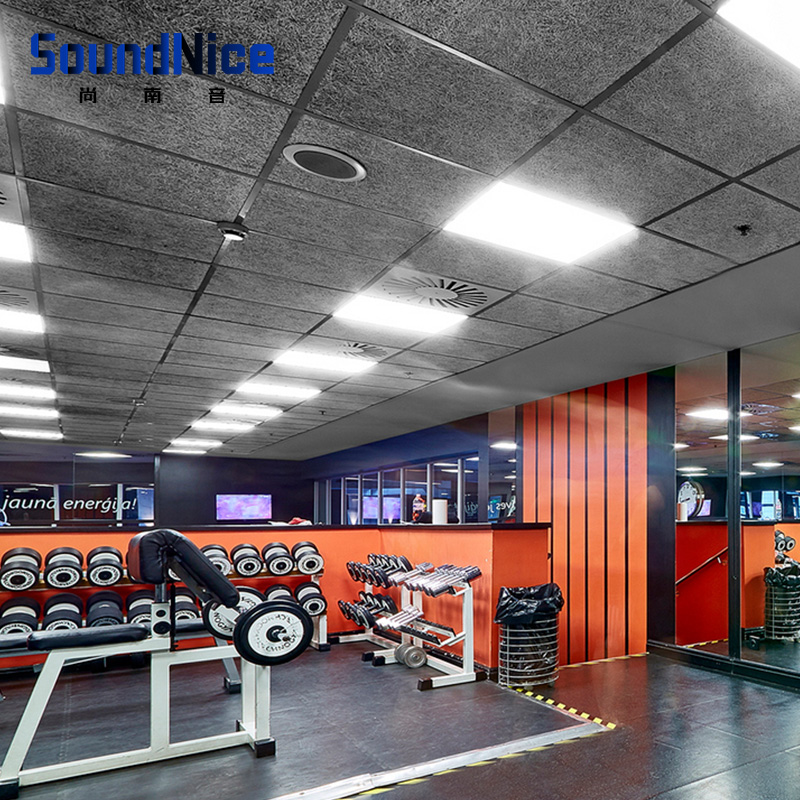

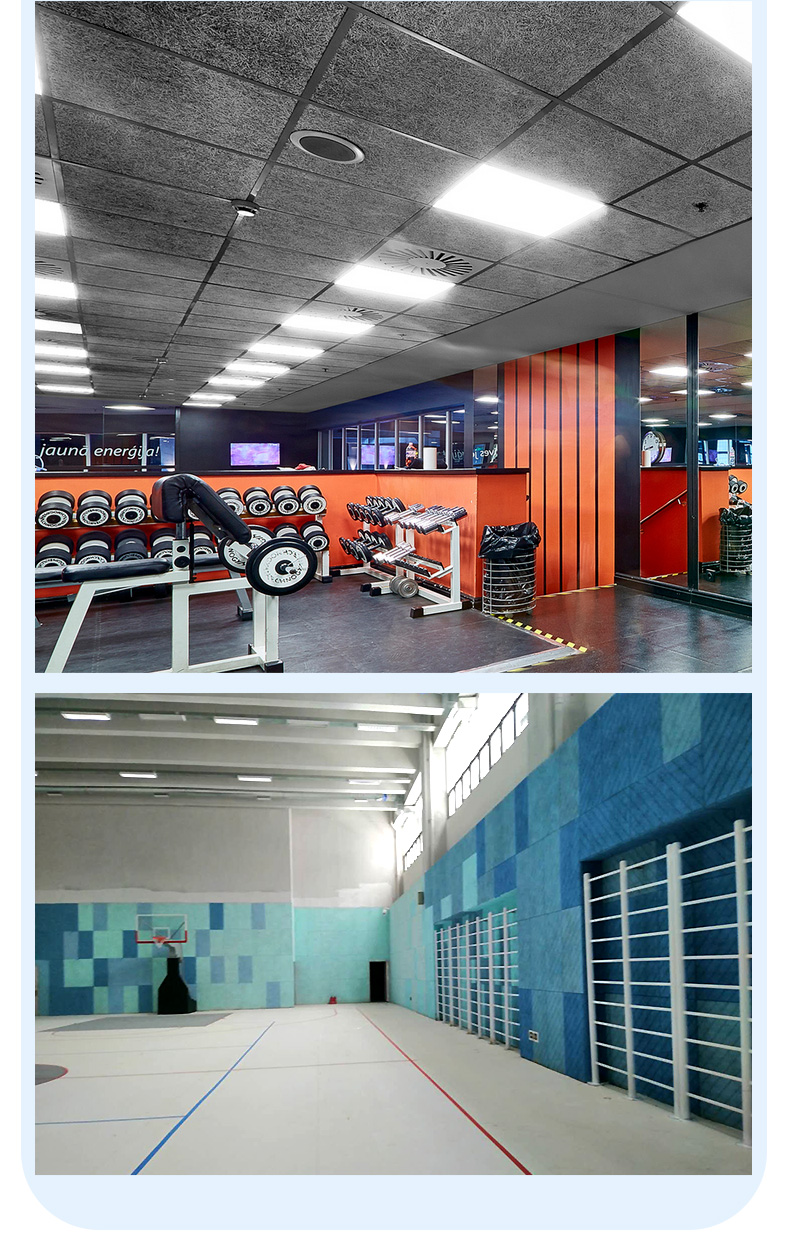

1) Strong structure-strong structure, full of elasticity, impact resistance, can withstand repeated impacts of basketball, football and volleyball without cracks or breakage when used in gymnasiums.

2) Simple installation—easy to cut, simple installation method, just general woodworking tools.

3) Antibacterial and moisture-proof — 25mm panels can be used under 85% humidity conditions, including open air and swimming pools, except for places that directly contact water.

4) Energy-saving and heat preservation, long lifespan—Because it is mainly made of wood, it has strong heat insulation performance. Economical and durable, long service life, can be customized size according to requirements.

B.Application space

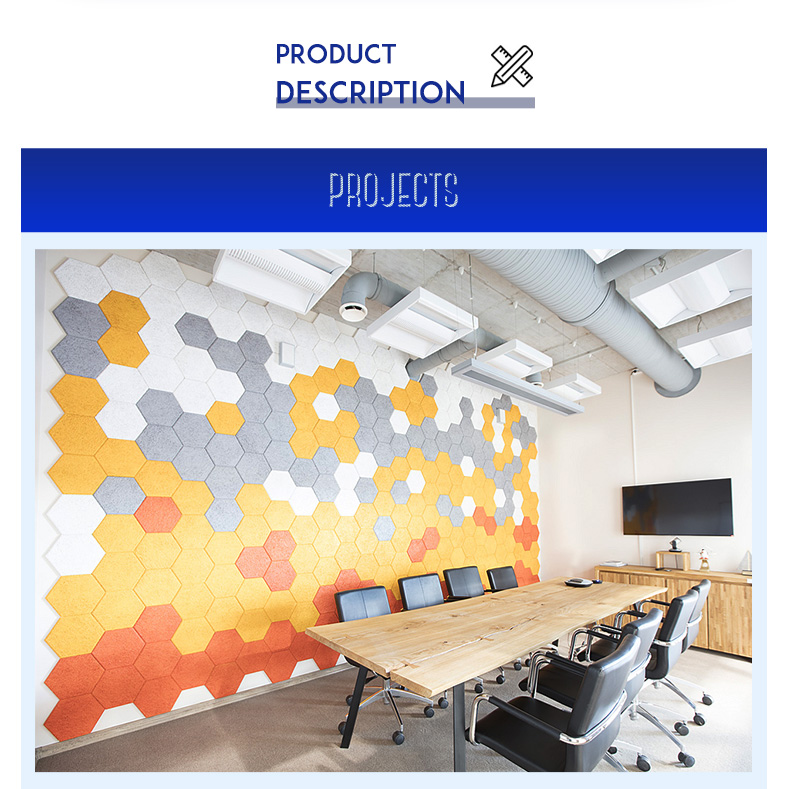

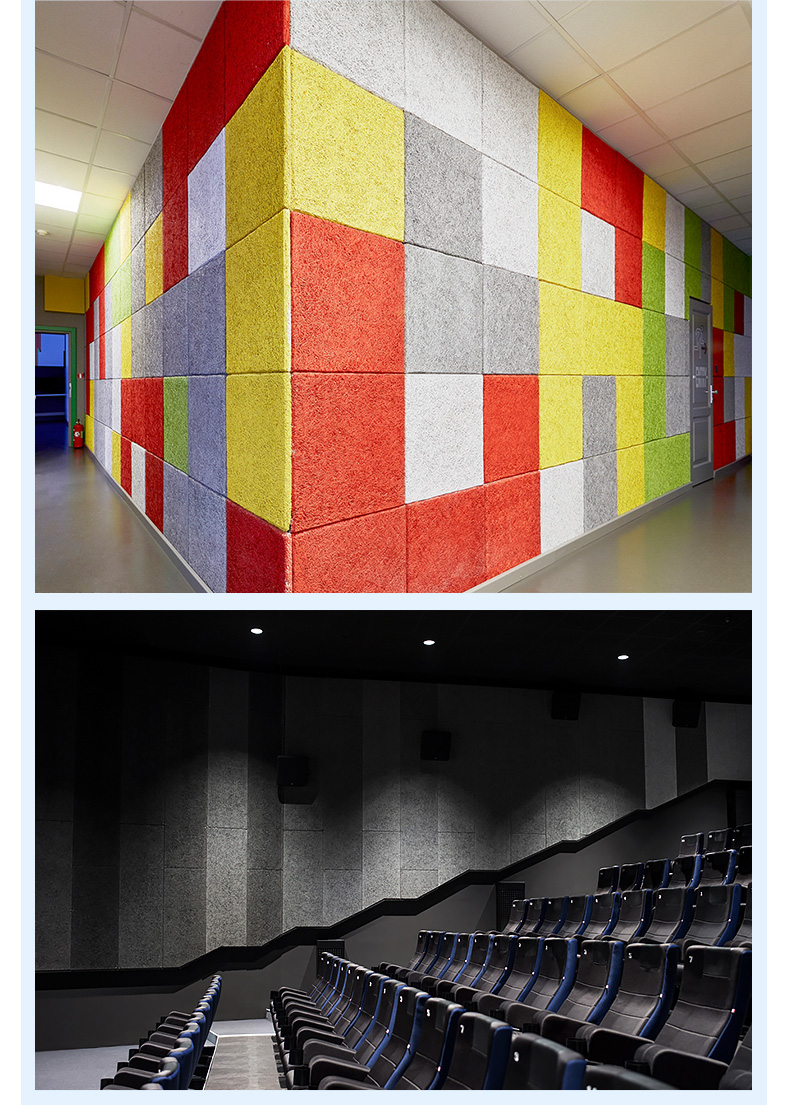

Applicable places: gymnasiums, swimming pools, cinemas, conference rooms, lecture halls, multi-function halls, schools, museums, libraries, hospitals, tunnels, bars, entertainment venues and other spaces that need sound absorption.

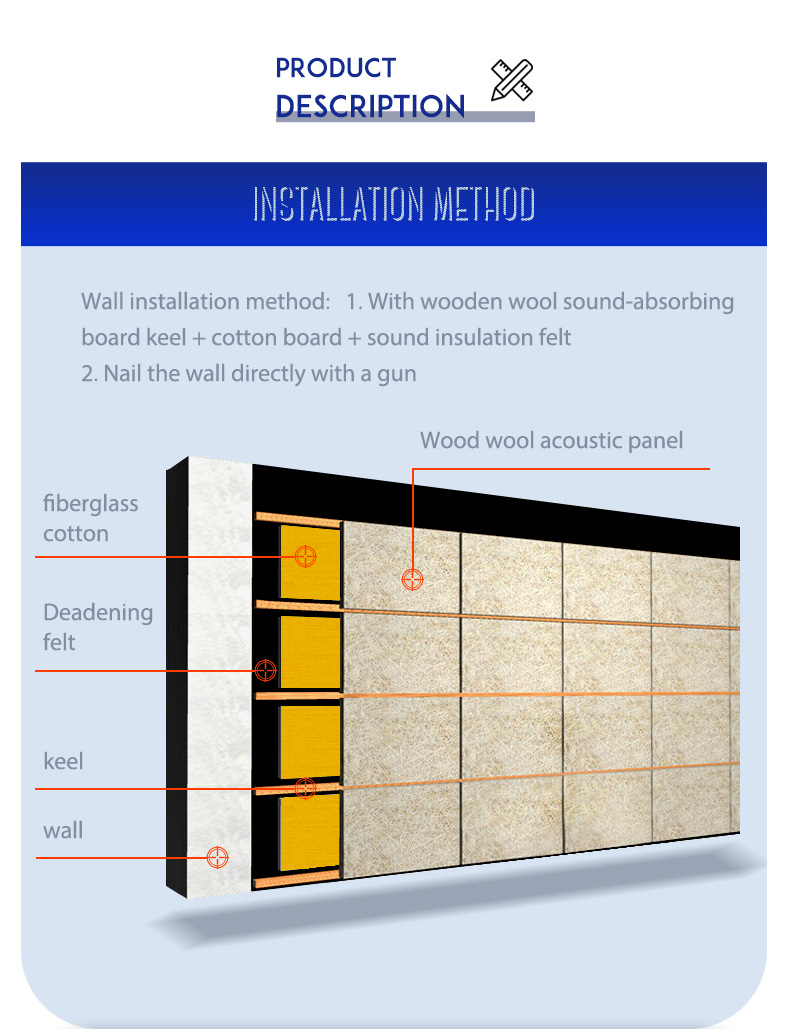

C.Wall mounting method

1)Advance the base surface, keep the construction surface dry and clean, and it is strictly forbidden to construct on the wet base surface. Because it is damp or unclean in the closed condition, it is very easy to produce some unhealthy bacteria, which can lead to mildew on the wall.

2)In the case of a keel, ordinary stainless steel nails are obliquely nailed from the side of the wood wool sound-absorbing board with a thickness of 20mm, and the keel is generally a sharp gun nail.

3)Light steel keel, when the high-rise building or the fire protection level is higher, the construction of wooden keel may not be allowed, generally a small piece of wood washer is fixed on the light steel keel by explosive screws, and then the wood wire is used. The sound-absorbing board can be fixed on the veneer.

4) If there is no keel on the wall, use glass glue or other glue to directly bond the wood wool sound-absorbing board. If possible, you can fix it with sharp gun nails at the corners.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.